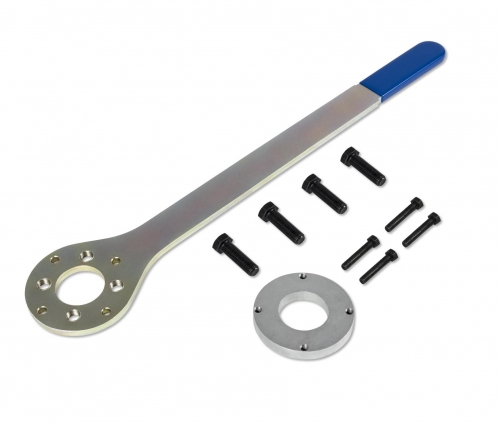

The gear (Pulley) puller is designed to remove motor, blower pulleys, and flywheel, etc., that have become frozen to the shaft.

Instead of trying to loosen a stuck pulley by hammering on it, the pulley puller creates uniform and leveraged pressure. This helps prevent damage to a motor's

bearings or creating misalignment to the shaft.

Drop forged, heat treated steel jaws. Hardened and tempered, precision-machined and black finished steel center screw.

Inside/outside reversible hooked jaws.

| Spread (mm) | Reach (mm) | |

| 3" | 75 | 60 |

| 4" | 100 | 70 |

| 6" | 150 | 120 |

| 8" | 200 | 175 |

| 10" | 250 | 190 |

| 12" | 300 | 215 |

| 14" | 350 | 250 |

| 16" | 400 | 285 |

| 20" | 500 | 360 |

How to choose a correct puller?

- Choose the spread: the width of the component to be pulled.

- Choose the reach: the depth of the component to be pulled.

- Choose the force: extra force will be required for difficult to remove, rusted on components. Choose a hydraulic puller for extra force.

What are some safety tips for using gear pullers?

Gear pullers are made in various shapes and sizes and have many uses. Always use the correct tool for the job.

- Wear safety glasses or goggles, or a face shield (with safety glasses or goggles).

- Select the proper gear puller for each job. Always use a gear puller of the required size or larger. Use a 3-jaw puller, if possible.

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD HKD

HKD JPY

JPY RUB

RUB CNY

CNY SGD

SGD NZD

NZD FJD

FJD