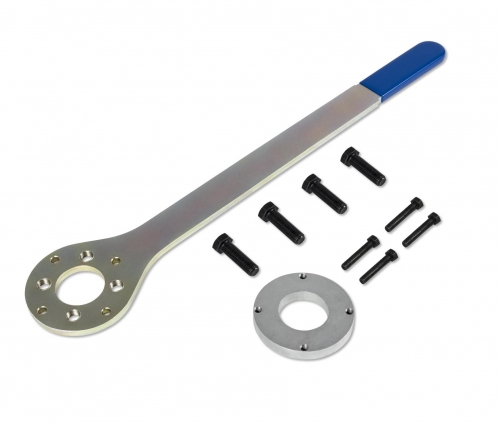

Torque angle gauge for fasteners where some manufacturers are specifying both torque and angle settings. With this gauge the professional mechanic can meet the demands of the new specifications to turn the fastener a specified number.

Tough composite dial and rotating index line allow operator to accurately tighten fixing to manufacturers exact specification. Supplied with fully adjustable reaction arm. Essential measuring tool for the busy workshop.

Designed to be used with any 1/2"Sq drive torque wrench.

Tough composite dial and rotating index line allow operator to accurately tighten fixing to manufacturers exact specification.

Gauge with adjustable angle scale

Locking L-type arm supplied

Essential measuring tool for the busy workshop.

Application:

Many late model engines have "Torque to Yield" (TTY) head bolts that are designed to stretch slightly when tightened. The torque specifications for these bolts often involve extra procedures, such as gradually tightening down the bolts in steps until a certain torque value is reached, then giving the bolt and extra twist (specified in number of degrees) to achieve its final load.

For these kinds of applications, you will need an extra tool called an Angle Gauge (see photo below) or an electronic torque wrench that can also measure the degrees of rotation as a fastener is being tightened. If you are using an angle gauge, mount it on the end of your torque wrench. Zero the pointer, then note how many degrees you have rotated the fastener as you are turning it.

USD

USD EUR

EUR GBP

GBP CAD

CAD AUD

AUD HKD

HKD JPY

JPY RUB

RUB CNY

CNY SGD

SGD NZD

NZD FJD

FJD